MODERN PRINTING

How the Times was produced by Steam—Molding and Stereotyping —Type-setting Machinery.

FOR hundreds of years the methods of printing which had been invented in the fifteenth century remained almost unchanged. The type was set by hand and printed in flat presses, and inked by means of large round pads of leather stuffed with wool. These balls were as much as twelve inches in diameter, and the apprentice whose task it was to spread the ink upon the type used two of them, dabbing one against another and working them against the face of the type with a twisting motion. It was a slow operation and a troublesome one, and required much practice before the operator became perfect at his task. The boys who did the work were known as printers’ "devils", no doubt because the ink spread over their hands and faces gave them a distinctly impish appearance.

The first improvement, and one which eventually opened the way to the invention of the modern printing machine, was the substitution of a roller for these balls. The roller was a cylinder made of hard wood and covered with a composition of glue and treacle, which was both soft and elastic and would easily take up the ink. The presses, too, were improved. The first were built of. wood with screws, made like the old-fashioned cheese press. Late in the eighteenth century iron presses were substituted for the old wooden ones. Earl Stanhope made such a press in 1798, and this was provided with levers which pressed down the "platen" (that is, the flat plate which overlies the paper and receives the pressure) with more force than the old hand press. His new press was found to give a much clearer impression of the type than the older methods.

The hand press, worked by skilled men, gave at most two hundred and fifty impressions per hour, and it was becoming more and more difficult for newspapers, even with the limited circulation of those days, to satisfy their readers’ demands in the way of circulation. Also, as we have already seen, steam power was rapidly coming in to work all kinds of machinery, and it was evident that it could be only a matter of time before printing would be done by machinery.

The first attempt to effect this was made in the year 1790 by Nicholson, who patented a rotary printing press, but it does not appear that he ever constructed one. Twenty-three years later, in 1813, Bacon and Donkin took out a patent for another printing machine, also on the roller principle, but this was not a success. Then came the invention of Cowper, who first had the idea of taking a cast of the type and bending the cast round a cylinder. Cowper was really the first of modern printers, but he was forestalled by Frederick Koenig, who, in 1814, set up steam-driven printing machinery for Mr. Walter, proprietor of the Times newspaper.

Koenig was a Saxon who in 1802 devised an improved printing machine with a movable carriage, inking rollers, and a new method of taking off the impression by flat pressure. As he could find no one in Germany to take up his new invention he came to England, where he worked at the printing office of Richard Taylor in Shoe Lane. Taylor introduced him to Thomas Bensley, a well-known printer in Bolt Court, Fleet Street, and in 1807 Koenig and Bensley went into a sort of partnership. This gave Koenig a chance to prepare plans of an improved machine, but it took him three years to perfect it and make a working model. This was shown to Mr. Walter, but at first he refused to have anything to do with it.

Koenig, however, constructed his machine, and it was set up in April 1811, when the Annual Register of that year was printed on it. This machine still had the old flat platen, but now it occurred to Koenig to use a cylinder instead. Two other well-known London printers joined Koenig and Bensley in the manufacture of Koenig’s new machines, and in 1812 one was made which would take off impressions at the rate of eight hundred an hour.

Again Koenig approached newspaper proprietors, Mr. Perry of the Morning Chronicle and Mr. Walter of the Times. Mr. Perry would not even go to see the new machine; but Mr. Walter, though he had refused Koenig’s first machine five years earlier, decided to see it. He was so deeply interested that before he left the premises he had ordered two of the machines.

The parts were prepared in a factory in Whitecross Street, and taken with the greatest secrecy to the premises of the Times in Printing House Square. Yet even so, rumors got afloat about the new machine, and the printers vowed a terrible vengeance upon the alien inventor who threatened their craft.

Excitement steadily increased, for it was said that the new machines were being put together. A general strike was threatened. One night the whole staff were told to wait in the pressroom because important news was expected from abroad. That was the night of November 28, 1814. At six o’clock next morning Mr. Walter, who had been watching the machines all night, walked into the room and quietly announced, "the Times has been printed by steam." He added a warning that if any attempt was made at violence a force of police was ready outside, but that, if the men remained peaceable, their wages would be paid as usual. That paper, the first ever printed by steam, tells its own story in the following words:

Our journal of this day presents to the public the practical result of the greatest improvement connected with printing since the discovery of the art itself. The reader of this paragraph now holds in his hand one of the many thousand impressions of The Times newspaper which were taken off by a mechanical apparatus. A system of machinery almost organic has been devised and arranged, which, while it relieves the human frame of its most laborious efforts in printing, far exceeds all human powers in rapidity and dispatch. That the magnitude of the invention may be justly appreciated by its effects, we shall inform the public that after the letters are placed by the compositors, and enclosed in what is called the "forme", little more remains for man to do than to attend upon and watch this unconscious agent in its operations. The machine is then merely supplied with paper, itself places the forme, inks it, adjusts the paper to the forme newly inked, stamps the sheet, and gives it forth to the hands of the attendant, at the same time withdrawing the forme for a fresh coat in ink, which itself again distributes, to meet the ensuing sheet now advancing for impression, and the whole of these complicated acts is performed with such a velocity and simultaneousness of movement that no less than 1100 sheets are impressed in one hour. That the completion of an invention of this kind, not the effect of chance, but the result of mechanical combinations, methodically arranged in the mind of the artist, should be attended with many obstructions and much delay may be readily admitted. Our share in this event has, indeed, only been the application of the discovery, under an agreement with the patentees, to our own particular business; yet few can conceive, even with this limited interest, the various disappointments and deep anxiety to which we have for a long course of time been subjected.

Of the person who made the discovery we have little to add. Sir Christopher Wren’s noblest monument is to be found in the building which he erected: so is the best tribute of praise which we are capable of offering to the inventor of the printing machine comprised in the preceding description, which we have feebly sketched, of the powers and utility of his invention. It must suffice to say further, that he is a Saxon by birth, that his name is König, and that the invention has been executed under the direction of his friend and countryman, Bauer.

On December 3, 1814, the Times speaks again of its new methods:

The machine of which we announced the discovery and our adoption a few days ago has been whirling on its course ever since with improving order, regularity, and even speed. The length of the debates on Thursday, the day when Parliament was adjourned, will have been observed; on such an occasion the operation of composing and printing the last page must commence among all journals at the same moment; and starting from that moment we, with our infinitely superior circulation, were able to throw off our whole impression many hours before the other respectable rival prints.

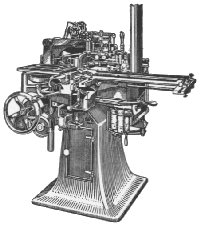

Koenig afterward returned to Germany, where he started a factory and made a large number of his machines for various Continental firms. Like so many other inventors, Koenig suffered from his early struggles, and died at the comparatively early age of fifty-eight. The firm founded by him, Koenig and Bauer, is still one of the most active makers of printing machines for printing magazines, etc., on varying sizes of paper. The earlier machines printed upon a flat bed, and the introduction of the cylinder or rotary press increased the output four or five times.

While Koenig was busy with his steam-printing machinery for newspapers, the Englishman Cowper, already mentioned, was working upon a new machine for printing wall papers. This was so great a success that it was adapted for printing the one-pound notes then issued by the Bank of England, and over four million notes were printed, each in two colors. Cowper went into partnership with Mr. Applegath, and the two proceeded to improve enormously upon Koenig’s early machine. They produced a four-cylinder machine capable of printing between four and five thousand sheets an hour. The firm of Cowper and Applegath flourished for many years, and by 1848 had produced an eight-cylinder machine which would print as many as ten thousand sheets. English inventors led the world in printing-press inventions for thirty years, but with the work of the Hoe family in New York the leadership swung to America between 1830 and 1840 and has remained there ever since.

Between 1856 and 1862 a number of great English newspapers fitted their works with these remarkable machines. The ten-cylinder Hoe press was driven at the rate of thirty-two revolutions per minute, and turned out ten thousand complete copies in an hour. For nearly twenty years this was the champion press of the world. I might mention, by way of comparison, that the modern printing machines turn out copies of an eight-page newspaper at the amazing speed of over two hundred thousand an hour; and these are not only printed by the machine, but also neatly folded.

Speeds such as these would have been impossible but for the invention of stereotyping. So long ago as 1730 an Edinburgh goldsmith named Ged invented a method of stereotyping. He used liquid stucco, which he poured over the types, and this, when solid, gave a perfect mold. Into the mold molten metal was poured, and a plate was thus produced which was a duplicate of the type itself. Ged obtained the privilege of printing Bibles and prayer books after this method, and hoped to make a fortune. Like many other unlucky inventors, however, he forgot the hatred inspired in workmen by any new labor-saving device. His compositors battered and spoiled his stereotype plates, and the unfortunate Ged was ruined and died in poverty.

But an invention which is of enormous importance to mankind cannot be destroyed by ignorant tyranny. It was revived in Scotland, France, Germany, and America, and Lord Stanhope, to whom printing owes so great a debt, made experiments with it between 1790 and 1800. Yet it was not for another half-century that stereotyping came to its own. The inventor of the modern method was an ingenious Italian named Dellagana, who discovered that

|

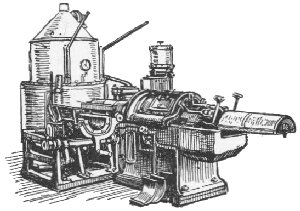

At first each column of type was separately "stereoed", but soon it was found that an impression could just as easily be taken of an entire page. The impression is taken in Papier-mâché, and rapidly dried on the same press, an example of which, from a model manufactured by Messrs. Koenig and Bauer, is shown in the illustration. The mold is then placed in a casting box, which is either flat or curved to the same radius as the cylinder of the printing press, and liquid metal is poured into it. Thus a metal plate is obtained which, when trimmed, is ready for printing. The advantages of such a plate are easily seen, for not only is the plate solid and perfectly shaped, either to a flat bed or to the drum or cylinder, but also any number of casts may be taken from the same mold. This makes it possible to have several machines printing the same plate at the same time, with no extra labor in the composing room. The plates, when finished with, can be melted and the metal used again and again.

Printing machines have been constantly improved, and

|

never a year goes by without further improvements. Today the machine room of a great newspaper provides one of the most interesting sights in the whole range of human industry.

As methods of printing improved, and as the spread of education and the increase of population sent up the circulation of newspapers to figures previously undreamed of, owners of newspapers found themselves confronted by another problem. This was to set up type as rapidly as the printing machines required. It was no use being able to print papers at the rate of twenty to fifty thousand an hour if the compositor could not set up the type in a proportionately short space of time. So inventors everywhere began to work to produce a machine which could set type quicker than by hand. Hundreds of patents were taken out, but it was

|

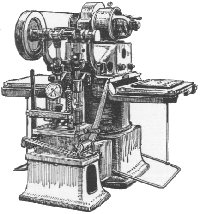

As the operator taps a key the machine takes a brass die from its place and sets it in the line; and as each word is completed, a "space" is placed against the last die so as to separate it from the next word. The line being complete, a bell rings, just as in the typewriter, and the whole line is automatically pushed away to a place against a little pot of molten metal kept always at the proper heat by the flame of a Bunsen burner. The machine then proceeds to pour out a sufficient amount of the type metal on to the line of brass dies. This hardens almost instantly, and the line of type slides out into a galley—a flat, oblong tray—which is all ready for it. So line after line is prepared, the speed being six times that at which the most expert worker can set type by hand.

The most marvellous part of the linotype machine is the mechanism which restores the used dies each to its

|

Although the linotype machine was used originally for newspaper work its field of action now extends to book printing and general commercial work.

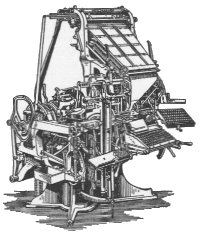

Even more amazing and intricate is the monotype, with its two hundred and twenty-five keys to provide the characters and spaces; the original model was invented by Tolbert Lanston, a native of Troy, Ohio. There is a machine for composing the matter, and this is worked by an operator who perforates a paper strip from a keyboard much like that of the typewriter. The strip is transferred to the casting machine, which it automatically controls, and the types are cast, not in whole lines, but in single letters. Types of many varied "founts", or patterns, are produced by the machine. The monotype is what may be called a "fool-proof" machine, for, should the compositor make a mistake so that the line is too long or too short, an automatic device comes into play which slips the driving belt from the fixed to a loose pulley and stops the whole machinery.

The monotype is generally preferred for composing and casting types

|

In both machines one of the most important features is that used types are melted down for service again and again. This saves the very considerable time needed for distributing handset types—that is, sorting them out, letter by letter, for return to their respective cases.

Another beneficial result of the use of type-setting machines is the healthier conditions which it provides. The friction of the hand types in the cases, combined with the natural oxidization that is always taking place, causes a poisonous dust to accumulate, which is injurious to the compositor. Lead poisoning is the result of this dust being taken into the system. Mechanical composition has changed this, for there is no lead dust on machine-composed type, and there is an absence of oxidization on account of the oil absorbed on the type surface during casting. Operating the keyboard is a clean, pleasant, and interesting occupation compared with picking types from a case. At the caster there is no possibility of danger to health, as there are practically no fumes arising from the molten lead at the temperature at which it is used.

Chapter 16

Chapter 14

Table of Contents

Return to Main Page

© 2002 by Lynn Waterman